The guarantee of product quality for injection molding machine manipulators starts from the morning meeting every Monday

For the quality of our products, Runma has always been certified. Last week, Dong Mingzhu gave a public speech in Shenzhen with the title: If you have someone else in your heart, you will definitely succeed. His core content has always been innovation around his products, pursuing the spirit of craftsmanship, and constantly innovating products around the thinking of customers. So we are also the same. For the peripheral products of robotic arms, injection molding machine robotic arms have always been our main products. We hold morning meetings every week, and the content of the morning meetings is also focused on discussing product quality. From the beginning of design, to the production process, and the purchase of materials, communication and cooperation are required layer by layer. Once there are some problems in any link, our commitment to customers may be delayed in the cycle, and the selection of supplier products may also result in defective products. This will directly lead to the inability to achieve excellence in the quality of injection molding machine robotic arms. Therefore, in production, we first ensure the quality of products, and secondly, the production efficiency of products. Firstly, our design department supervisor Li reported the issue he encountered last week and requested some cooperation.

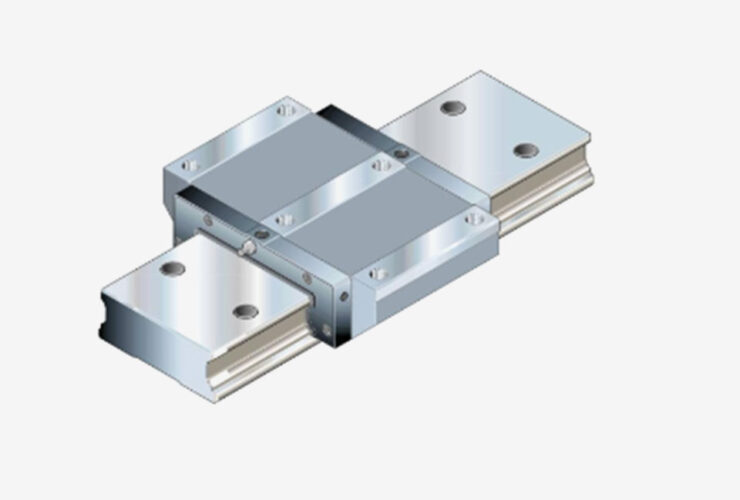

Then our production department representative pointed out the coordination points they need. Currently, the supply of materials may not be able to keep up, and the specific fixture selection for the injection molding machine manipulator is uncertain. This led us to replace one batch today and say it was the wrong one. Tomorrow, we will replace another fixture, which is a waste of time and reduces production efficiency. We hope that the next time the design department determines the accessories for the product, they will ask us to install them and the warehouse will directly supply the materials to us. This way, such errors will not occur, and production efficiency will be greatly improved without unnecessary waste of manpower and time.

Finally, our production manager Deng summarized. Firstly, our meeting gathers everyone for the purpose of improving the production quality and efficiency of our products. As long as our quality meets the standards that others cannot, our products can gain an advantage in the market, rather than engaging in price wars like before. Moreover, our quality is excellent, our efficiency is fast, and we have always been able to meet customer delivery times. Therefore, I believe that one of Runma’s core products, injection molding machine manipulators, will soon gain a lot of favor in the domestic market. But how many accessories are needed for the injection molding machine robotic arm? This also means that not all of our suppliers can deliver on time and strictly control the quality of our products. Therefore, we need to constantly communicate and adapt internally, so that we can cooperate more smoothly and produce our products with high quality and efficiency. There are always problems. Through morning meetings, we summarized last week’s work and prepared for improvement this week’s work content.