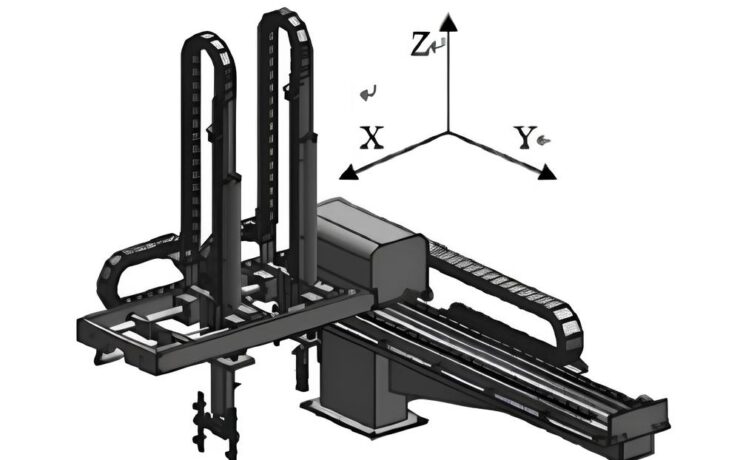

What is the reason for the deviation of the robotic arm?

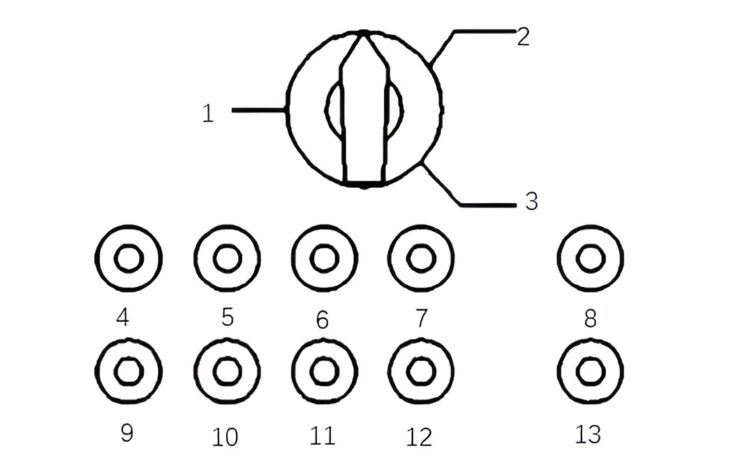

1) Reason for malfunction: (1) The inside of the oil cup is too dirty, the filter is clogged, or the oil level in the cup is low. (2) There is a large amount of air in the power steering system. (3) There is a foreign